Our Services

Home | Services

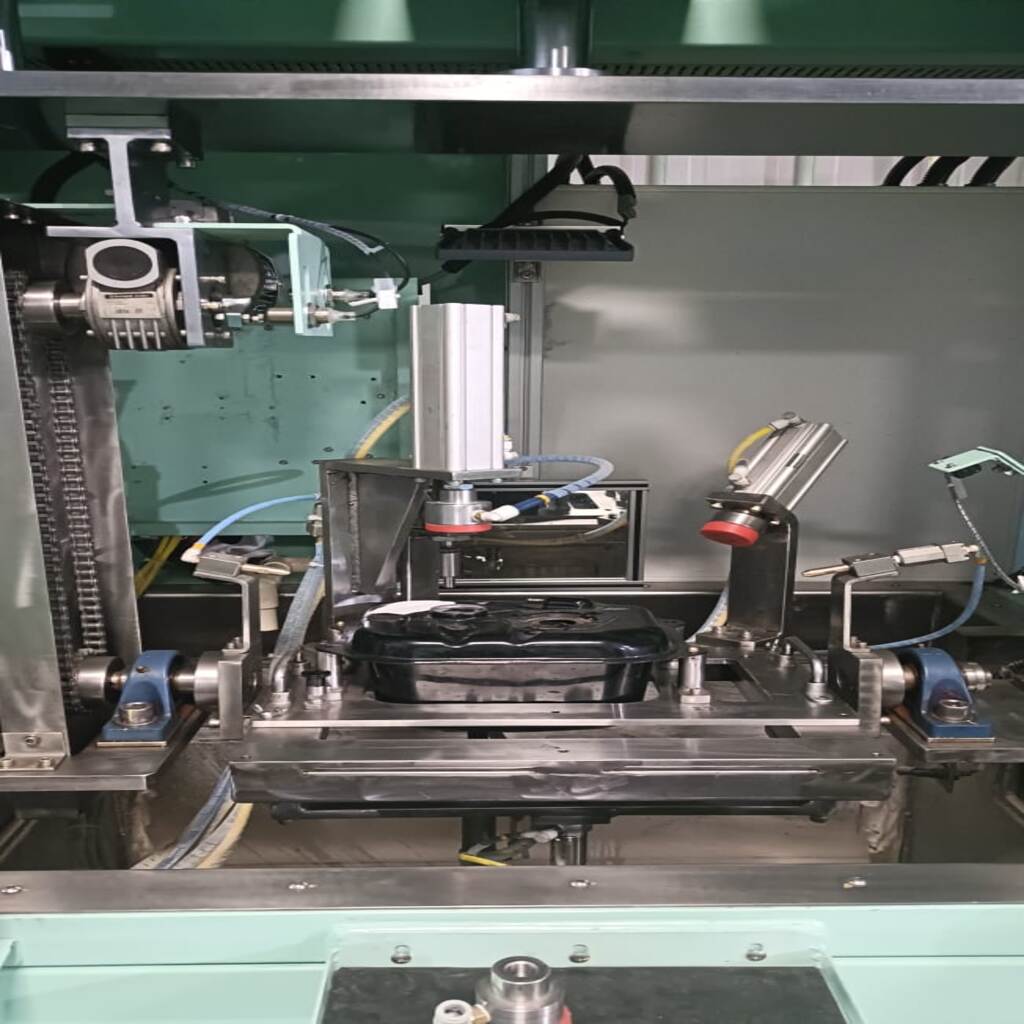

Assembly Lines

Our custom assembly lines are designed to optimize production efficiency and precision. From manual workstations to fully automated robotic systems, we deliver solutions tailored to industries like automotive, auto components, and more, ensuring seamless integration and scalability.

- Customized automation for small to large-scale production

- Integration of PLC, HMI, and SCADA systems for advanced control

- In-house design, fabrication, and installation services

- Serves OEMs, Tier 1, and Tier 2 automotive companies

Leakage Testing Machines

We engineer high-precision leakage testing machines to ensure component reliability in demanding applications. Our machines are designed for testing components such as cylinder heads, CNG hoses, and gear box housings, meeting stringent industry standards.

- Custom solutions for components like turbine housings and flywheels

- Advanced sensors and data logging for accurate leak detection

- Applications in automotive, rubber, and nylon industries

- Examples: K8 Cylinder Head LTM, Breather Hose LTM

Industrial Washing Machines (Ultrasonic/Jet Type)

Our industrial washing machines, including ultrasonic and jet-type systems, provide thorough cleaning for complex components. These machines are ideal for automotive housings, link shafts, and other parts, ensuring contaminant-free surfaces with minimal environmental impact.

- Ultrasonic cleaning for intricate and delicate components

- High-pressure jet systems for robust cleaning applications

- Customized for front/rear housings and link shaft brackets

- Eco-friendly processes with efficient waste management

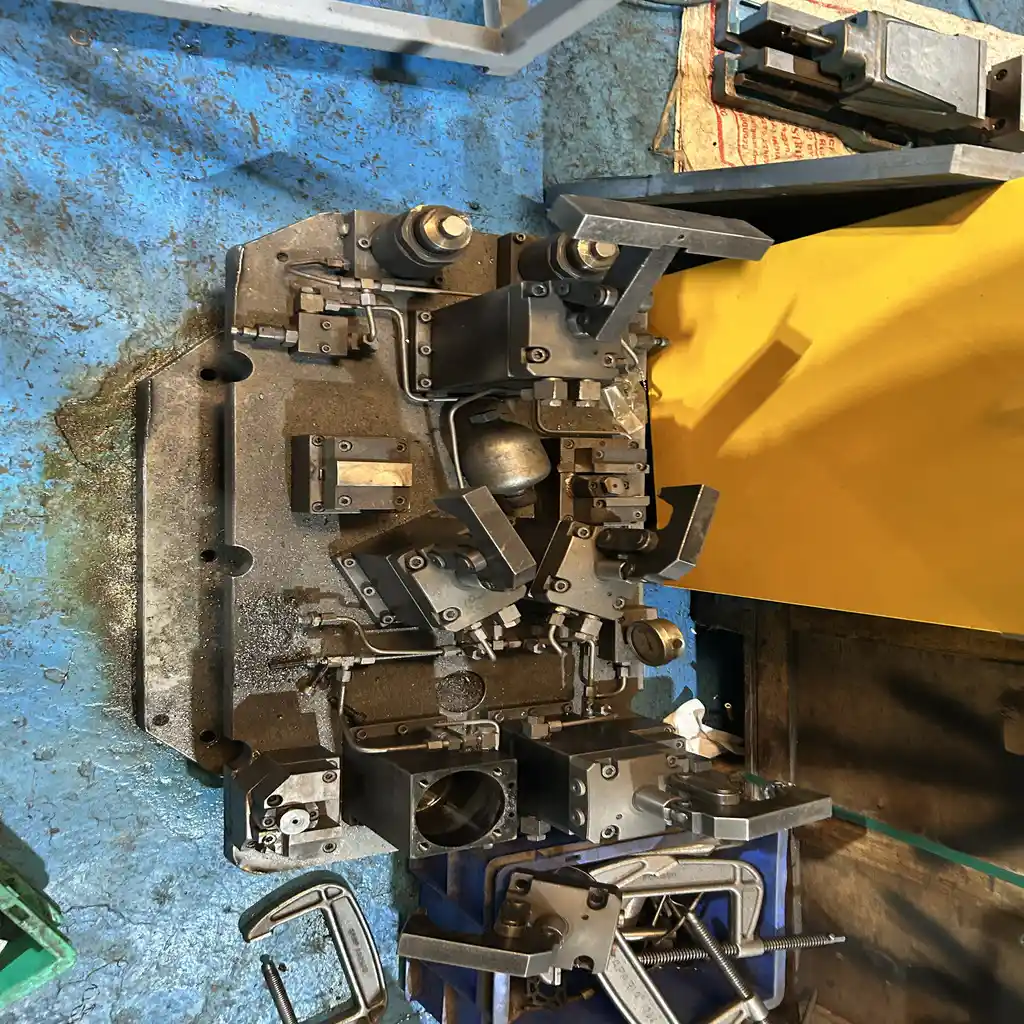

Leakage Testing Fixture

We design and manufacture machining fixtures for Vertical Machining Centers (VMC), Horizontal Machining Centers (HMC), Vertical Turret Lathes (VTL), and turning chucks. These fixtures ensure precise positioning and stability, enhancing machining accuracy and efficiency.

- Custom fixtures for complex mechanical components

- Designed using SolidWorks and NX 10.5 for precision

- Applications in automotive, heavy machinery, and die casting

- Support for 5-axis VMC machining processes

NEED HELP!

Ready to Transform Your Operations?

Partner with Pioneer Tools Design and Engineering to unlock innovative, precision-engineered solutions tailored to your needs. From assembly lines to leakage testing machines, we deliver excellence every step of the way.

(1800) 88 66 996 | Support@gmail.com

Vision Inspection Systems

Our vision inspection systems leverage advanced imaging and AI technology to ensure product quality. These systems are designed for non-destructive testing, defect detection, and dimensional verification in high-volume production environments.

- High-resolution cameras with AI-driven analysis

- Customized for automotive, nylon, and rubber components

- Seamless integration with existing production lines

- Ensures compliance with industry quality standards

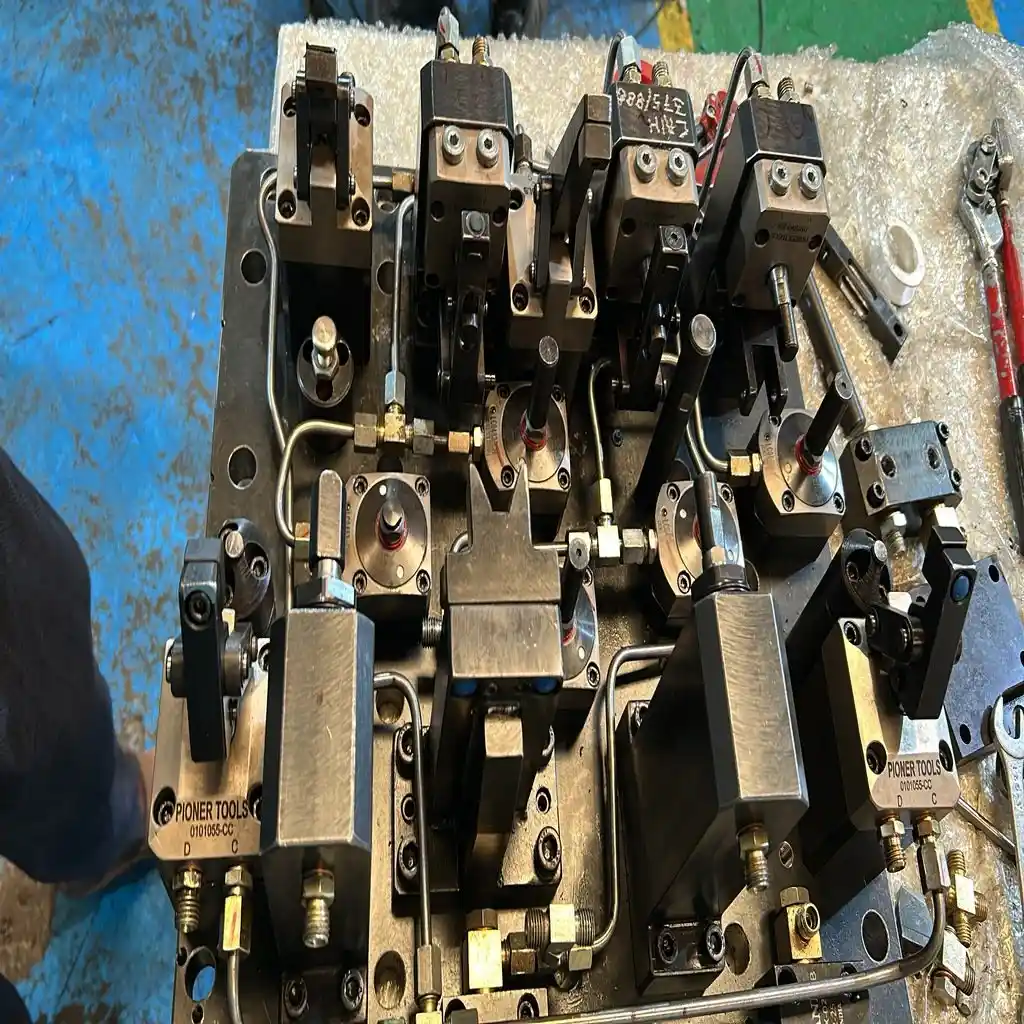

Gauging Fixtures

Our gauging fixtures are engineered for precise measurement of components during production. These fixtures ensure dimensional accuracy and compliance with industry standards, minimizing errors and reducing rework.

- Customized for specific component geometries

- High repeatability and accuracy in measurements

- Applications in automotive and rubber industries

- Compatible with CMM inspection systems

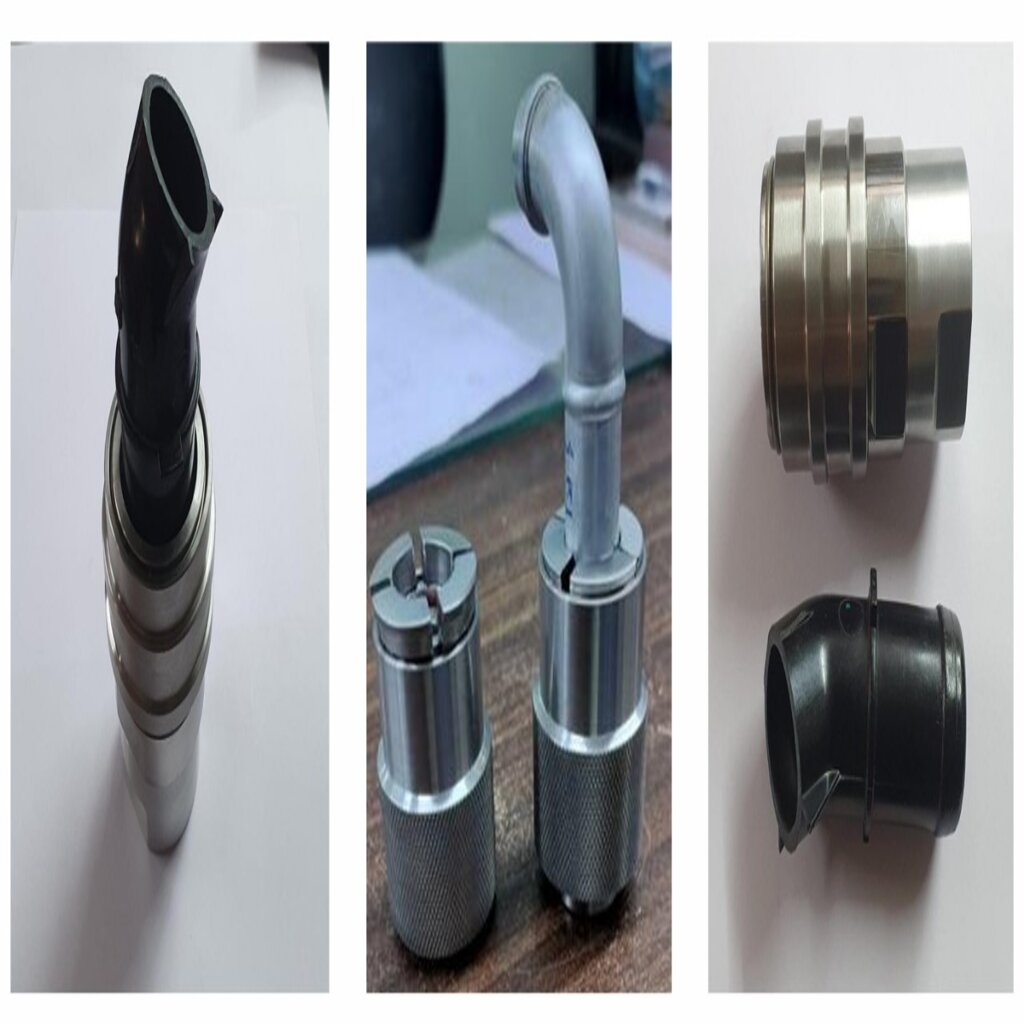

Pneumatic Couplers

We provide high-performance pneumatic couplers for reliable connections in automation systems. Designed for durability and efficiency, these couplers ensure leak-free performance in assembly lines, testing machines, and other applications.

- High-durability materials for long-term reliability

- Custom designs for specific pneumatic systems

- Applications in automotive and industrial automation

- Quick-connect solutions to enhance productivity

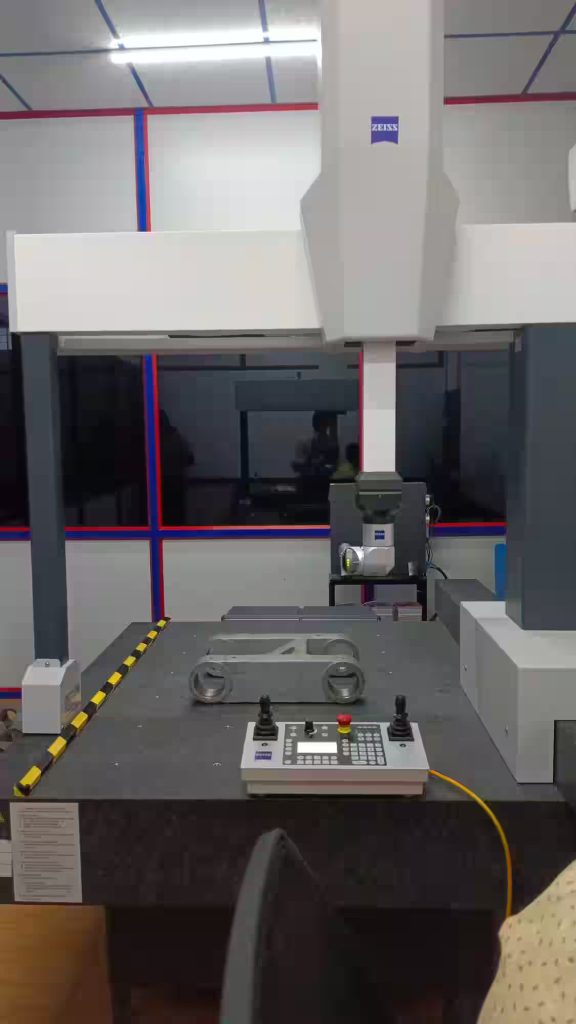

CMM Inspection Services

Our Coordinate Measuring Machine (CMM) inspection services ensure top-notch quality control for precision components. Using advanced CMM technology, we verify dimensional accuracy and compliance with industry standards for a wide range of applications.

- High-precision measurements for complex geometries

- Serves automotive, rubber, and nylon industries

- Detailed reporting and data analysis

- Integration with in-house design and manufacturing

How It Work?

Consultation & Concept Development

We begin by understanding your needs and goals through in-depth consultations. Our team collaborates with you to develop tailored concepts for solutions like assembly lines, leakage testing machines, or custom fixtures, ensuring alignment with your specifications and industry standards.

Design & Engineering

Using advanced CAD tools like SolidWorks and NX 10.5, our experienced design team creates precise, innovative designs. We handle everything in-house, from mechanical design and programming (PLC, HMI, SCADA) to fabrication, ensuring high-quality, customized solutions.

Manufacturing & Installation

Our state-of-the-art manufacturing facilities, including 5-axis VMC machining, produce your solution with precision. We manage installation and provide after-sales support, ensuring seamless integration and long-term performance with on-time delivery.

Your One-Stop Solution for Engineering Excellence

Why Choose Us?

- Fast service with on-time delivery to meet tight schedules

- Competitive pricing without compromising quality

- Experienced team with over 10 years of expertise in design and engineering

- Advanced CAD tools (SolidWorks, NX 10.5) for precision design

- Comprehensive in-house capabilities from concept to after-sales support

- Continuous investment in technology to stay ahead of industry trends

We listen to our clients, understand their goals, and craft solutions through ingenuity, collaboration, and transparency—values that have defined us since day one.

Quick Links

About

Team

Contact us

Locations

Get in Touch

Email: pioneertooldesign@gmail.com

Phone: +91 7755929070,

+91 7972050011,

+91 8393821194

Address: Plot No-14, S-block, MIDC, Bhosari, Pune-411026, Maharashtra

© 2025 Pioneer Tools Design and Engineering. All rights reserved.